metal stamping machine operator job description

Cycle time is used to express the total manual work involved in a process or part of a process. 1097 stamper machine 1098 stamping-machine operator 1099 stamping-machine operator 1100 stamping-mill tender 1101 stamping-press operator 1102 stamp-pad finisher 1103 stamp-pad maker 1104 standards engineer 1105 stand-in 1106 standpipe tender 1107 staple cutter 1108 staple-processing-machine operator.

In most modern shops the items are scanned by a barcode positioned on the item with the use of a laser scanner.

. See the Emergencies page. We also have machine cycle time which is the start-to-start time of a machine and is used to balance to a manual work cycle and in conjunction with the batch size is a measure of its theoretical capacity. Duties and responsibilities include formulating policies managing daily operations and planning the use of materials and human resources but are too diverse and general in nature to be classified in any one functional area of management or administration such as personnel.

Frequently gold colored but available in many colors. See this page for contact details. 31 064 030 324.

The purpose of these standards is the protection of life the promotion of health and safety and the prevention of accidents. The most common types are blue stainless and high-carbon steel. Plan direct or coordinate the operations of public or private sector organizations.

It allows the cut and suspended material room to exit the deck without getting recut. Deep mower-deck stamping gives excellent cut quality. Numerical control also computer numerical control and commonly called CNC is the automated control of machining tools such as drills lathes mills and 3D printers by means of a computerA CNC machine processes a piece of material metal plastic wood ceramic or composite to meet specifications by following coded programmed instructions and without a.

ELECTRICAL-DISCHARGE-MACHINE OPERATOR PRODUCTION 3412 ELECTRICAL-DISCHARGE-MACHINE SET-UP OPERATOR 3413. Our list of over 12000 Job and Career Descriptions. CUT-OFF-SAW OPERATOR METAL 2629 CUT-OFF-SAW OPERATOR PIPE BLANKS 2630.

After all of the goods have been scanned the cashier then collects the payment in cash check andor by. Enter the email address you signed up with and well email you a reset link. The key difference among tools is the type of steel used for the blade.

6PM to 9PM weekdays. Then metal sheet that is applied to paper using the foil stamping process. 107-cm Accel Deep MulchControl lever action Model year 2016 and newer X300 Series Tractors Z300 Series ZTrak.

107-cm Accel Deep MulchControl lever action. Productivity - gets the job done fast. This part 56 sets forth mandatory safety and health standards for each surface metal or nonmetal mine including open pit mines subject to the Federal Mine Safety and Health Act of 1977.

Pinch type machine 2. No loose metal powders or lasers and very little operator intervention required the system makes it. It simplifies engine starts and warm-up by eliminating the need for the operator to use a choke.

The worlds first office-friendly metal 3D printing system the Studio System is an ideal solution for applications that span a variety of industries including manufacturing tooling automotive consumer electronics and oil gas. Please Login to see scheme specific contacts. Steel trowels look similar to hand floats except the blades are thinner and the handles are open rather than closed.

Sign-In Cart. Pyramidal type machine This machine is of pinch type here only the top roll serves as a driven bottom roller are idler and rotates on friction with the work metal blank. In a shop a cashier or checkout operator is a person who scans the goods through a cash register that the customer wishes to purchase at the retail store.

Deep mower-deck stamping gives excellent cut quality. We would like to show you a description here but the site wont allow us. See a sample of foil embossing.

They are as follows. Career Testing Since 1997 cplan10. Sheet Metal Rolling Machine is classified into two types based on the arrangement of the rollers.

Used after floating to produce a smooth hard dense slab surface. It allows the cut and suspended material room to exit the deck without getting recut. Stamping a thin sheet of metallic foil onto a sheet of paper and then embossing a pattern under it creating a three dimensional raised area usually text or an image.

Discover recipes home ideas style inspiration and other ideas to try.

Old Heavy Machinery Metal Working Machines Lathe Machine Machine Tools

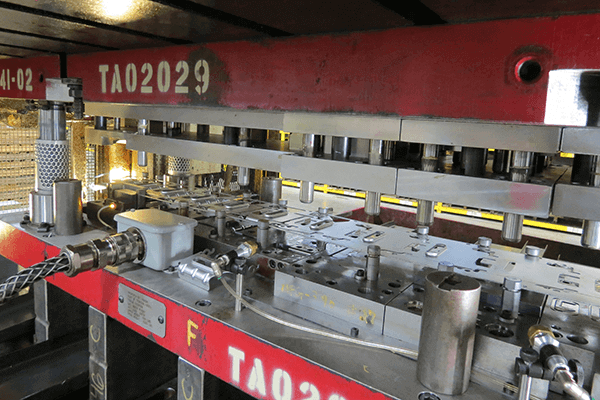

Production Monitoring Of A Metal Stamping Press Cas Dataloggers

Metal Stamping Services Ultra Tool Manufacturing

Cnc Milling Services Thuro Metal Products Inc

.jpg)

What Do Cutting Machine Operators Do Including Their Typical Day At Work

How Does A Stamping Press Work Phoenix Specialty

Metalworking Images Stock Photos Vectors Shutterstock

A Meaningful Review Of Metal Stamping And Safety Mcr Safety Info Blog

Metal Fabrication Industry Mcr Safety

![]()

5 Reasons To Become A Press Brake Operator Badger Sheet Metal Works

Metal Stamping Services Ultra Tool Manufacturing

Metal Stamping Services Ultra Tool Manufacturing

High Volume Stamping For Progressive Die

Custom Perforated Metal Panels Perforated Metal Products

Metal And Plastic Machine Workers Jobs Career Salary And Education Information

5 Reasons To Become A Press Brake Operator Badger Sheet Metal Works